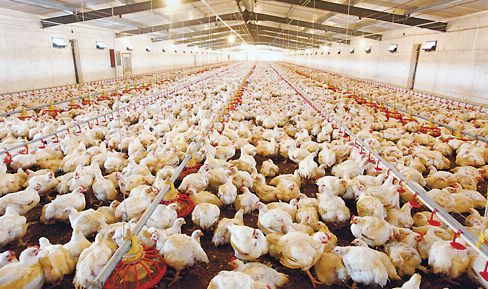

Ventilation is especially important for farmers who uselayer rearing equipmentand broiler rearing equipment to raise chickens. The cage mode is generally a closed chicken house. If the farmers are not ventilated in time, the harmful gases in the house will not be discharged, which will pollute the flock and cause disease. Nowadays, the common ventilation method of the house is to use the fan equipment for ventilation. The following describes the type of fan equipment.

1. Axial fan: The air that the fan draws in and sends out is parallel to the direction of the fan blade shaft. The characteristic is that the direction of rotation of the blade can be reversed, the direction of rotation changes, the direction of the airflow changes, and the amount of ventilation does not decrease. Axial fans can be designed in a variety of sizes and air volumes and can be installed anywhere in the house. Among them, the low-pressure and large-flow axial flow fan adopts the twisted surface of the twisted surface, and the ratio of the radial component of the rotor to the axial component will increase with the length of the blade. Combined with the small arc inlet of the collector, a hemispherical uniform inlet airflow model can be formed.

The dynamic pressure is small, the static pressure is moderate, and the noise is low. In addition to obtaining a large flow rate and significant energy saving effect, the entire intake air flow distribution between the fans is also relatively uniform, which is of great benefit to the production process and airflow organization. As the blinds matched with the fan, it is now possible to open and close the mechanical transmission, and use FRP as the louver, which is not easy to deform and at the same time anti-corrosion. The number of blades and the angle of the blades and the rotational speed of the fan all affect the air volume and wind pressure. Many domestic manufacturers produce 6 axial fans, but some manufacturers produce 2, 3, 4 fan blades with 15°. There are five kinds of blade installation angles of 20°, 25°, 30° and 35°. The air flow can reach up to 60,000 cubic meters/h, but the matching motor power is large.

2. Centrifugal fan: When the fan is running, the airflow is driven by the centrifugal force formed when the working wheel with blades rotates. Therefore, when the air enters the fan and is parallel to the blade axis, it becomes a vertical direction when leaving the fan, which makes it adapt to the 90° turn of the ventilation pipe. The centrifugal fan consists of a snail-shaped housing, a working wheel and a base with a drive wheel. The air enters the fan from the air inlet and is fed by the centrifugal force formed by the rotating bladed working wheel, flows through the working wheel and is sent into the outer casing, and then sent into the air duct through the air outlet of the casing. Centrifugal fans are not reversible, and the pressure is strong. In the ventilation and ventilation system of the barn, most of them are used when sending hot air and cold air.

3. Ceiling fan and peripheral fan: The ceiling fan and the peripheral fan are placed on the inner wall of the ceiling or wall to blow the air directly to the chicken body, thereby increasing the airflow speed in the vicinity of the chicken and promoting evaporation and heat dissipation. Generally, as an auxiliary equipment for naturally ventilated chicken houses, the installation location and quantity depend on the condition of the house.

The above is an introduction to ventilation equipment. The above ventilation equipment is the most commonly used when using laying equipment andautomatic broiler cage systemequipment.