With the improvement of the research and development level of animal husbandry equipment in recent years, the development of automation level has been greatly promoted. According to the authors, coupled with the sharp increase in labor costs, workers urgently need to reduce the actual situation of labor intensity and a large number of knowledge. The addition of young professionals in technology has led to a significant increase in the incentives of aquaculture companies to invest in automation equipment.

The feeding equipment of laying hens has also undergone tremendous changes along with the development of the animal husbandry. The battery mode of laying hens has been widely recognized by the laying hens and the development prospects are promising.

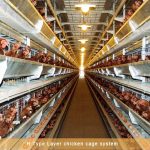

Thebattery layer cageequipment is the first choice for large-scale, intensive, automated and standardized laying hens at home and abroad.

It has the following advantages: small footprint, high space utilization, easy to achieve intensive and large-scale breeding; chicken manure layering clean, natural air drying makes chicken manure water greatly reduced, chicken manure utilization is high, and environmental pollution is minimal Fully automated control, greatly reducing the number of operators, reducing labor intensity and increasing labor productivity; adopting a fully enclosed feeding mode is conducive to preventing the occurrence of infectious diseases and improving the production performance of the flock.